Rockwell Automation threw a party, and more than 10,000 of its closest friends showed up. Such was the case at the recent Automation Fair, an annual exhibition, training and technology event hosted by the Milwaukee-based automation solutions provider, Nov. 16 and 17 in St. Louis. The Fair—which features exhibits from Rockwell Automation Inc. and its partners—provides a free educational forum to promote manufacturing technology and application successes.

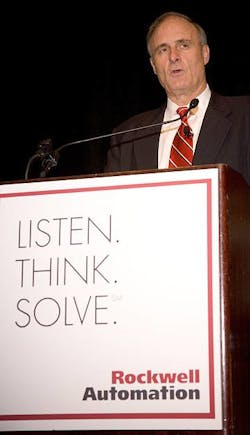

In his keynote address at the Manufacturing Perspectives 2005 event, held on Nov. 15 and attended by more than 80 manufacturing media and analysts from around the world, Keith Nosbusch, chairman and chief executive officer, commented, “What makes Rockwell Automation different? Our people, innovation, customer relationships, channels and partners. Customer intimacy is a sustainable, competitive advantage.”

It is customer intimacy that has helped Rockwell Automation post 2005 sales figures of $5 billion, an increase of 11 percent over 2004, Nosbusch contends. While the automation market itself grew at a rate of about 5 percent in 2005, Rockwell Automation added to that 5 percent growth with about a 3 percent growth in served markets and share, a 2 percent growth due to globalization, and just better than 1 percent in price increases.

According to Nosbusch, the high-growth areas for the company include its integrated architecture initiatives; integrated safety and automation; batch and hybrid automation; motor controls; and expansion in targeted industry verticals. Noted Nosbusch, “We’re more than 100 years old, yet we continue to innovate, even in the commodities-based segment of the market.”

Process transparency

William C. Taylor, president and chief executive officer of Mercedes-Benz U.S. International Inc., a DaimlerChrysler company, addressed the Manufacturing Perspectives audience with comments on how Rockwell Automation helped his company achieve transparency into the manufacturing process.

Taylor was part of the Mercedes-Benz team that, in 1993, selected Tuscaloosa County, Alabama, in which to build a new manufacturing site—its first plant outside of Germany. Said Taylor, “This was a learning process and a melting pot of German, U.S. and Japanese ways. We needed an available workforce, proximity to a port, the presence of a university and a good business climate.”

A recent expansion has more than doubled the plant’s size to 3 million square feet under one roof. Its 4,000 employees, or “team members,” as Taylor calls them, have a 1 percent turnover, 99 percent attendance rate and are responsible for 20 percent of Mercedes-Benz’ gross revenue. The factory builds the second-generation M-Class vehicles and the newest Mercedes-Benz line, the R-Class.

Mercedes selected Rockwell Automation as its automation partner for the plant because, said Taylor, the company “provides the expertise needed for the long haul.” Software jointly developed by Rockwell Automation and DaimlerChrysler supports a library of standardized instructions and process transparency that has improved problem solving in the plant.

About the Author

Jane Gerold

Automation World

Leaders relevant to this article: