Combined Expertise to Help Chinese and Indian Life Sciences Companies Meet U.S. Regulatory Standards

Increasing governmental regulations, as well as new requirements that mandate compliance with U.S. Food & Drug Administration (FDA) standards and other food safety regulations, have made it imperative for life sciences companies operating in China and India to be able to accurately track products at all points in the manufacturing process. Such track-and trace capabilities ensure safe and high-quality products, and enhance the abilities of companies to respond to problems.

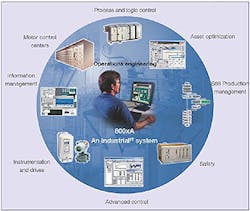

To assist in those efforts, Zurich, Switzerland-based ABB, maker of power and automation technologies, and system integrator Zenith Technologies announced that they will work together to develop and implement automation solutions for life science customers in China and India. Headquartered in Cork, Ireland, Zenith Technologies is a global automation and manufacturing execution system (MES) system integration company that focuses exclusively on the life science industry. ABB will collaborate with Zenith to implement solutions based on ABB’s System 800xA and Freelance automation systems. ABB and Zenith will also deliver solutions that use ABB’s MES and process analytical technology (PAT) technology.

“ABB’s field-proven automation solutions, combined with Zenith’s expertise in implementing systems designed to meet these validation requirements, will help our mutual customers in this region improve their overall process and product quality, and meet current and future regulations,” said Tobias Becker, head of ABB Control Technologies. “Our collective knowledge can help our customers better understand how these requirements impact their manufacturing process and what steps are needed to comply with them.”

Earlier this year, Dewas, Ranbaxy, one of India’s largest pharmaceutical & life sciences companies, announced that it had chosen ABB’s System 800xA technology for its upcoming CLA/ CILIM facilities at Dewas, located in the Central Indian state of Madhya Pradesh. The 800xA system reportedly “will offer Ranbaxy several features including the Audit Trail with Batch server, and conformance to FDA regulation of 21 CFR Part11, a mandatory requirement for exports to Europe and USA.” ABB’s IndustrialIT based System 800xA was recently launched in India and approximately 800 engineers from around the world worked on the project, including 50 research engineers from ABB’s Corporate Research Centre in Bangalore, India.

Zenith has a presence in the U.S. market, with U.S. headquarters in Framingham, Mass. as well as offices in Philadelphia and Raleigh, N.C. and Irvine, Calif. Zenith’s offerings include advanced e-learning solutions designed to train technical personnel at operations facilities in any global location. The intuitive and interactive instruction model is optimized to deliver customized, accessible technical training to maximize production and personnel efficiencies while reducing manufacturing risks. An overview of the training offerings is available on YouTube.

Renee Robbins Bassett