Collect Data Automatically

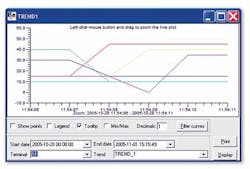

“The most obvious advantage is the automated handling,” says Anders Nilsson, marketing manager at the vendor. “In an industrial network, the user can easily define what parameters to save from the different machines and processes. After that, everything is handled automatically.” Sample intervals can be set to correspond to specific process needs or quality guidelines. The software also supports Ethernet and modem communication, making it possible to automatically collect data from geographically separated facilities. Trends, data, alarms and other data that have been stored in a database can easily be view and checked in a Viewer, which is part of the Data Collector software. Data Collector requires Windows XP/NT/2000. The data can be stored in a standard database such as SQL, Access or MSDE.