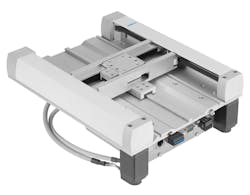

Among the products showcased at the Festo stand at the 2013 Hannover Fair was a product for precise and fast positioning in cramped installation conditions—Festo H-gantry EXCM. It is a compact planar surface gantry that can approach any position within its working space. The recirculating toothed belt moves the slide within a two-dimensional area (X and Y axes). The fixed motors are connected to the slide; moving masses remain low because of the parallel-kinematic drive principle.

This ready-to-install system allows fast positioning at speeds of up to 500 mm/s and repetition accuracies on the order of ±0.05 mm. This makes the compact H-gantry suited to applications in electronics production and small parts assembly.

The gantry requires very little commissioning. and can be integrated quickly into machines. It has a pre-parameterized drive and controller package, and the flexible interface concept provides users with a choice of Ethernet, CANopen and I/Os for up to 64 positions.

About the Author

Gary Mintchell

Editor in Chief

Leaders relevant to this article: