One of the reasons, cited in Jim Koelsch’s excellent article in July on virtual plant technology (visit bit.ly/awfeat079), is more affordable computing platforms with more accessible user interfaces. The design of accessible user interfaces is huge as more operators are asked to do more in plant settings. Virtual tools need to be easy to grasp, with small learning curves. As mentioned in the virtual plant article, “70 percent of operators ‘touch’ simulation now and then. They have day jobs and aren’t going to become simulation experts.”

Speaking of experts, I ran into some smart simulation engineers at a recent ISA water and wastewater symposium, held in early August in Orlando, Fla. One presentation—“HMI Testing of Multiple PLCs Using Simulations on Virtual Machines” by Marcelo Avendano, automation specialist for CDM Smith and Kevin Patel, project manager for CDM Smith—offered a quick tutorial on how to get started with virtual software. The presentation cited an opportunity to reduce hardware costs for big installations, such as a reduction of 20 machines down to four. Other benefits cited in the presentation include remote troubleshooting with actual configuration, energy efficiency and improved capacity, to name few. Negatives of virtual technology can be increased impact of hardware failure, and software licensing.

For more insights on simulation, visit bit.ly/awsimulation

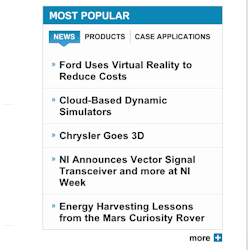

Looking for more modeling and simulation coverage? Here is a sampling of popular stories on AutomationWorld.com:

· Case Application: Simulating Control Schemes Proves Useful—Modeling and simulation technologies just keep getting better. Power plants and other facilities deploying the latest generation of software are reaping the benefits of faster validation, better optimization and more effective training. Visit bit.ly/awfeat075

· Perspective: Simulation Benefits for Medical Packaging Manufacturer—MTS Medical Technologies in St. Petersburg, Fla., makes medication packaging systems, related consumables, software and pharmacy information system interfaces. Visit bit.ly/awslant096· News: Chrysler Reveals 3D Technology—The 3D modeling system used by Chrysler’s powertrain manufacturing group is Create3D from Strategic Manufacturing Solutions (Auburn Hills, MI). According to Harlow, the software is used to “help everyone see the shop floor as it really is and not how one might imagine it is.” Visit bit.ly/awnews193· Blog Post: 3B Robotic Sensor—Using pattern projection based on the Kinect sensor principle used in consumer technologies such as the Xbox 360, this new robotic sensor combines two different sensor images to direct robotic gripping of objects. Visit bit.ly/awslant095Popular Video on AutomationWorld.com -

· Video: Ford: Simulation for Better Assembly. Visit bit.ly/awvids056

· Video: Mintchell: The Future of Industrial Computing. Visit bit.ly/awvids080

· Video: Cyber Security: SCADAHacker Presentation at TAC 2012. Visit bit.ly/awvids095

· Video: Automation Applied: Virus Prevention: Deep Packet Inspection. Visit bit.ly/awvids082

About the Author

Grant Gerke

Digital Managing Editor

Leaders relevant to this article: