Extending CAD for Additive Manufacturing

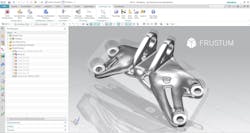

Following on the heels of its partnership with Stratasys, Siemens is extending its reach into the 3D printing/additive manufacturing market through a partnership with Frustum Inc. In this partnership, Frustum’s topology optimization and freeform geometry generator is now offered as an integrated module for Siemens NX software for computer aided design, manufacturing and engineering (CAD, CAM, CAE).

Frustum's topology optimization software is a generative design technology that is said to streamline a product's shape by automating weight and material reduction while still retaining structural integrity. Generative design is a category of software that automatically "generates" several design options based on input constraints such as material, function, weight and cost.

Adding topology optimization to Siemens NX reportedly allows for the generation of fully optimized, printable additive manufacturing designs. This capability reduces the costs associated with part redesign and post-processing that can benefit the aerospace, automotive and heavy machinery industries by creating components and parts optimized for lightweight yet stiffer designs.

Combining topology optimization with the Convergent Modeling technology available in the latest release of Siemens' NX is said to simplify the ability to work with a combination of facets, surfaces and solids, such as those created through topology optimization. Ultimately, this means that the integration of Frustum's technology with NX enables the creation of an optimized design that can then be quickly refined and made ready for additive manufacturing (AM) using Convergent Modeling.

Frustum says its technology allows engineers and designers to discover and deliver manufacture-ready parts and products with balanced performance, structural strength and weight. According to the company, designers can calculate, optimize, adapt and validate design options in parallel by running multiple scenarios while adding force application points and load cases. In addition, users can leverage Convergent Modeling to further edit or refine the results of a topology optimization study for greater design flexibility.

Speaking about this new partnership with Siemens, Jesse Coors-Blankenship, founder and CEO of Frustum, said, “the power of our technology and optimization framework…removes some of the barriers associated with additive manufacturing. We are excited to enable Siemens' NX customers to design fully optimized parts, ready for 3D printing, as well as empower them to move beyond the boundaries of traditional CAD geometry."

Bob Haubrock, senior vice president of product engineering software for Siemens PLM Software, added, "Frustum's unique technology…fits with Siemens' approach and vision to free industrial designers and engineers to create the next generation of parts and products that closely match customer needs, reduce energy consumption and drastically reduce the cost and time to market for these innovations."