Integrated Product Design, Engineering and Manufacturing Software

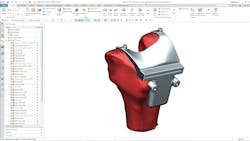

The new modeling paradigm simplifies the ability to work with geometry consisting of a combination of facets, surfaces and solids, without the need for time-consuming data conversion. It helps engineers optimize part design for 3D printing, speeds up the overall design process and makes reverse engineering a far more common and efficient practice in product design. Convergent Modeling gives designers the flexibility to rapidly create new optimal shapes leveraging the materials and techniques made available through additive manufacturing. It allows users to immediately begin using scanned data to create molds based on the shape, include it in an assembly, analyze it, or perform any other normal CAD operation. This, combined with the new 3D Print function that enables users to 3D print designs directly from NX, significantly simplifies the additive manufacturing process. The new scan, edit and print workflow uses the new Microsoft 3D print capabilities and supports the 3MF format to help ensure wide compatibility. In addition, it includes multiple enhancements throughout the integrated computer-aided design, manufacturing and engineering (CAD/CAM/CAE) solution, such as next generation 3D CAE, powered by the newly announced Simcenter 3D software, and improved CAM productivity with tools like robotics machining and hybrid additive manufacturing to help improve productivity.

>>For more information on this product, click here

Siemens PLM

http://www.plm.automation.siemens.com/en_us/

800.498.5351