SICK and Vention Partner to Bring Enhanced Robot Guidance Systems to Manufacturers

SICK is proud to announce its partnership with Vention, a next-generation manufacturing automation platform (MAP). This partnership combines SICK’s PLB and PLOC2D systems with Vention’s manufacturing automation platform to accelerate the design and deployment of applications custom-built for robot guidance systems.

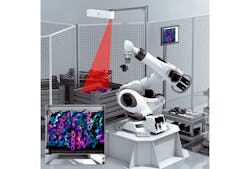

Vention’s cloud-based platform allows customers to design, automate, and deploy SICK robot guidance systems with 2D and 3D vision solutions for use in automated bin picking applications. SICK’s PLB and PLOC2D systems offer flexible robot integration functions that make them easy to use with any robot brand. This is further enhanced through the Vention platform.

“This partnership will enable customers to design, automate, and deploy custom-built robot cells with increased speed and simplicity. SICK and Vention's combined expertise, coupled with a shared dedication to customer service creates a compelling offering for a variety of customer needs, from novice to automation experts,” said Patrick Halde, Chief Business Development Officer at Vention.

The PLB 3D bin picking and PLOC2D vision solutions are already available for machine design on the Vention platform. The PLB robot guidance system provides flexible and reliable part localization for bin picking and depalletizing applications, regardless of part shape and orientation. A range of 3D cameras compatible with the PLB software provide high-quality images for reliable part localization, collision avoidance, and overlap detection. The PLOC2D robot guidance system provides an easy to set up and maintain browser-based interface and easy to use robot integration functions for 2D pick and place applications.

Image-based solutions help enlarge the field of vision for robots assisting with bin picking applications. The robotic system localizes and identifies the defined object, decides how best to grip the part. There is no need for mechanical attachments, like object guides, to accomplish bin-picking applications.

Robot guidance systems from SICK can be used across multiple applications, including robot cell integration, pedestal & workstations, conveyors, and cobot palletizers. SICK’s versatile product offering enables customers to design a modular robot cell in days.

“Our partnership with Vention provides distinct advantages to our customers looking for modular robotic solutions,” said Kam Yuen, Head of Market Product Management – Systems at SICK USA. “With Vention’s AI-enabled and cloud-based platform, our customers will be able to design, order, and assemble custom equipment to improve manufacturing processes.”

SICK intends to add additional product offerings to Vention’s platform to continue to offer customers modular solutions tailored to individual needs.