Riley Morgan is a hard-working, respectful 17 year-old from Georgia who likes cars, outdoor sports and video games. He’s a typical teenager in many ways, except for a special skillset that sets him apart from most of the 65 million others who make up Generation Z—also known as the iGeneration (iGen). He is a mechatronics major who is OSHA certified making him a coveted job candidate in the manufacturing industry.

Riley is a senior at the THINC College and Career Academy, a charter school in LeGrange that approaches education with business and industry needs in mind. The school offers five career pathways, including business and marketing, energy systems, STEM, health and sports medicine and mechatronics—all of which were selected through an employer survey.

Employers, in fact, are a big part of the process. THINC helps companies develop internships for high school students, an effort that is geared toward fostering a future workforce by engaging with kids at an early age. Educators and employers alike are trying new approaches when it comes to capturing students’ attention before they reach college. So THINC accepts students into its programs in the 9th grade, which is a good starting point. Each pathway program is three semesters, allowing students to take multiple pathways over four years, or return to their traditional high school.

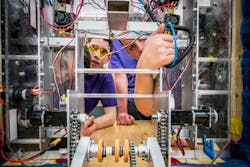

For Riley, it was his sophomore year, when he entered the mechatronics program at THINC, that was a life-changing moment.“I had no idea what manufacturing was before I entered ninth grade,” he said, referring to his transition from his previous school to THINC Academy. “In eighth grade I was focused on video game designs, but as soon as I got to high school, I realized it probably wasn’t for me.” This program saved him time, money and effort, he said. “Without THINC I would have gone to college for video design and would have found out it’s not for me. Instead, I found what I enjoy doing, which is engineering, robotics and focusing on mechanical and electrical, as well as gears and conveyors, all of the different systems that make a machine move.”

Indeed, it was his love of cars and his role model—his grandfather—that first influenced Riley. His grandfather spent a career in the automotive industry, often telling Riley stories about what he was working on and allowing his grandson to tinker with tools. These things sparked Riley’s interest at a young age as he wondered how it was that a piece of metal could move on the highway. At THINC, he could dig deeper. The students have a hands-on approach, looking at schematics and stripping wires, connecting power supplies and playing with PLCs.

But just as vital to the program are the soft skills that are taught in the classroom. The academic team feels it is just as essential to understand the mechanics of life, including: attendance, teamwork, problem solving, initiative, productivity, communication, cooperation, respect, appearance, attitude, sense of urgency, adaptability and attention to detail.

The students are graded on their ability to master these qualities as part of the curriculum.“We hear from employers that they can teach people, but they can’t keep people or they can’t get them to work on a team or they can’t communicate” says Kathy Carlisle, CEO of THINC. “So our students are graded on these soft skills every week, which is a huge aspect of the program.”

The students aren’t always too keen on this part of their schooling, admitted Riley, but, now, as a senior, he understands the enormous value of knowing the meaning of attendance and attire, for example. “When I first came here I was iffy about it, but I realized this would get me prepared for work and even college. Knowing how to dress, knowing I need to be in class or get to work on time, and knowing how to talk to people and having a strong work ethic is great knowledge to have at a young age.”

Riley, Carlisle said, is one of the many “stars” that this school—which is only in its fourth year—has proudly produced. These young adults are quickly recruited by the local corporations. Riley is currently working in a special apprenticeship program with Kia where he is moving between departments, working on general assembly of cars to paint maintenance to supplier quality and production control.

His goal is to be hired on to the Kia Motors Manufacturing Georgia team in the future. “I think I’d be a good addition,” he said.

So do we, Riley…so do we.

About the Author

Stephanie Neil

Editor-in-Chief, OEM Magazine

Leaders relevant to this article: