As service business models multiply and flourish, suppliers are finding new ways to take advantage of their in-house capabilities to provide extended services to customers. Microgrids—traditionally owned almost entirely by end users—are beginning to emerge with third-party ownership models, accounting for 46 percent of the new microgrid projects in 2017, according to GTM Research.

Schneider Electric has been offering its microgrid as a service (MaaS) to help manufacturers maintain an uninterrupted flow of electricity with more reliable and storm-resilient power. The supplier is also eating its own dog food, launching a series of microgrids at its own manufacturing facilities to get the same power resilience.

Its latest MaaS project—the third with Duke Energy Renewables and REC Solar—puts an advanced microgrid at Schneider Electric’s Foxboro, Mass., facility, which serves as the company’s Process Automation North American Power Generation Center of Excellence. It was less than a year ago that Schneider Electric unveiled the advanced microgrid at its Boston One Campus (BOC) in Andover, Mass., offering increased reliability, cost savings and sustainable energy production for critical R&D operations.

“Our customers demand power resilience from the microgrids we install at their sites, and our facilities rely on the same high standards to keep sites online in the event of a grid outage. Through our existing partnership with REC Solar and Duke Energy Renewables, we have seen firsthand the benefits of installing advanced microgrids at commercial and industrial facilities through the MaaS business model,” said Mark Feasel, vice president, utility segment, smart grid and microgrid, Schneider Electric. “This microgrid ensures the building will remain operational during unplanned outages in addition to optimizing the use of our on-site resources that demonstrate Schneider Electric’s commitment to sustainability.”

Adding microgrid and automation capabilities to backup generators—which are typically tied only to selected loads—can enhance resilience and prevent outages in the event of grid failure, allowing facilities to remain fully operational. That could save an average of nearly $16,000 for just a 30-minute power cut to a medium or large industrial facility in the U.S., according to a report from Allianz. Shorter blackouts account for an annual estimated economic loss of $104 billion to $164 billion, Allianz reports.

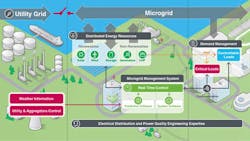

As part of the microgrid deployment at the Foxboro facility, Schneider Electric is also making use of much of the technology surrounding its EcoStruxure platform, an open and interoperable system architecture enabled by the Industrial Internet of Things (IIoT). Associated technologies include:

- The flagship EcoStruxure Hybrid distributed control system (DCS) will be used to connect all components of the architecture. The DCS offers advanced asset management capabilities and enables energy optimization and easy troubleshooting.

- EcoStruxure Profit Advisor and Termis District Energy Optimization Software will further optimize thermal distribution and energy costs. A patented IIoT software that uses Big Data analytics to measure and reveal the profitability of an industrial operation in real time, EcoStruxure Profit Advisor offers insight into how every production asset within the plant contributes to the operational profitability of the company.

- Onsite advanced microgrid control software and hardware will be provided through the use of EcoStruxure Microgrid Advisor and the Energy Control, in addition to the deployment of ongoing monitoring and services including turnkey implementation and engineering, procurement and construction (EPC). EcoStruxure Microgrid Advisor will help Schneider Electric track and make CO2 reduction measures visible to the facility managers.

Using its MaaS business model, Schneider Electric is able to build the microgrids without a need for upfront capital. As the investor owner of the project, REC Solar will fund, own and operate the microgrid assets.

“Microgrid as a service makes microgrids accessible to a wider variety of customers and has prompted innovation within the industry,” said Chris Hiller, lead solution architect for REC Solar. “By partnering with Schneider Electric, we have helped customers integrate microgrids with no upfront capital, while helping companies achieve more efficient and sustainable energy consumption.”