AI-Enabled ERP Is Closing the Automation Gap for Mid-Sized Manufacturers

Key Highlights

- AI-driven ERP can convert substantial automation investments into tangible operational improvements by closing the gaps between planning, execution and maintenance.

- Mid-sized manufacturers stand to gain the most from this approach, as AI lowers the historical barrier to modernizing outdated ERP systems by reducing reliance on custom code and manual processes.

- Start by baselining current operations, identifying and prioritizing high-value use cases and selecting scalable technologies to accelerate adoption and guarantee measurable results.

Manufacturers across the discrete, batch and process sectors consistently place automation at the zenith of their investment strategies. Multiple industry reports confirm that more than 60% of U.S. manufacturers rank digital transformation and automation as mission-critical priorities. And the outlook for this approach is clear: up to 30% of future productivity gains will materialize from the tighter, more intelligent integration of execution systems with core digital workflows.

Despite these postive numbers, I frequently see mid-sized firms strugging to translate significant capital investments in automation into sustainable operational gains. In my work advising executive teams and implementing manufacturing solutions, I can confirm that machines are rarely the bottleneck. The true challenge resides in the enterprise systems above the machines.

The reason for this is that effective automation hinges on timely, contextualized data. Unfortunately, many manufacturers are operating with ERP systems that were simply not designed or implemented to function at the speed required by a highly automated plant. As a result, planners lack visibility into real-time supply constraints. Maintenance teams are forced to rely on fragmented tribal knowledge because a unified view of asset health and performance is absent. Operators constantly employ workarounds just to keep production flowing.

The bottom line here is that, fundamentally, automation is outpacing the systems built to support it. But this is precisely where AI-enabled ERP emerges as a significant opportunity.

Why AI-enabled ERP is a game changer for discrete and batch manufacturing

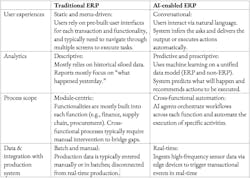

AI-enabled ERP is not merely an upgrade; it fundamentally strengthens the digital backbone manufacturers already depend on. It systematically eradicates the slow, manual steps that induce friction across planning, scheduling, quality and maintenance. Rather than being confined by static rules or outdated, custom-coded logic, AI-enabled ERP can dynamically interpret signals from across the plant floor and deliver recommendations predicated on true operating conditions.

Historically, an ERP modernization project meant a multi-year effort defined by large costs and significant operational effort. AI-enabled ERP overcomes this barrier by reducing the need for complex customization, shortening implementation cycles and providing built-in intelligence that rapidly adapts to shifting business conditions.

Common friction points to the integration of AI into ERP systems I consistently encounter include:

- Data fragmentation that isolates planning from production and maintenance.

- Lack of visibility into actual equipment health and condition. ? Excessive dependency on bespoke custom logic that quickly decays, locking teams out of adopting new capabilities.

- Execution data that rarely feeds back accurately into critical scheduling and capacity decisions.

AI redefines the role of ERP, evolving it from a passive system of record into a dynamic, adaptive decision-support engine that continuously learns from plant behavior and self-adjusts accordingly.

Unleashing value with AI-driven asset management

Asset management stands out as a functional area where AI-enabled ERP is delivering immediate, measurable value. For discrete and batch manufacturers, maximizing equipment uptime is fundamental to cost control, safety and throughput.

AI-enabled ERP can synthesize data that historically resided in isolated silos, including sensor signals, work-order history, maintenance logs and operator notes to forge a single, consolidated view of asset health. This robust foundation allows the system to accurately identify emerging risks, proactively recommend the most appropriate maintenance tasks and intelligently prioritize work orders based on their real operational impact.

Historically, connecting the shop floor to the top floor often failed because ERP systems are not built to handle raw, millisecond-level telemetry. An AI-enabled ERP, supported by the “contextualization layer” enabled by edge devices, solves this challenge. Instead of flooding the system with vibration data, for example, edge devices and the built-in algorithms filter the noise and transmit only business-relevant events, such as critical machine condition.

This also establishes a closed-loop process because the ERP doesn’t just observe; it responds. It can push updated commends back to the edge, such as halting a machine or adjusting production setpoints to ensure the shop floor aligns with business priorities.

In one mid-sized process manufacturing facility I worked with, the maintenance team spent most of its time responding to machine downtimes. Everything they did was manual, data was scattered and technicians relied heavily on personal knowledge to decide what to fix next. As a result, it was nearly impossible to predict failures or spot patterns because every incident was handled as a one-off event.

AI-enabled ERP fundamentally shifts this all-too-common dynamic for maintenance teams. By feeding equipment telemetry, maintenance schedules, historical failure data and technician notes into a unified model, the system can highlight assets at risk and provide the explanation behind the diagnosis. Maintenance teams transition from reacting to breakdowns to prioritizing interventions based on actual conditions, which significantly reduces unplanned downtime and makes day-to-day operations far more predictable.

Rather than being confined by static rules or outdated, custom-coded logic, AI-enabled ERP can dynamically interpret signals from across the plant floor and deliver recommendations predicated on true operating conditions.

The data confirms this practical reality: predictive and AI-assisted maintenance strategies have been shown to cut maintenance costs by 10-40%, reduce unplanned downtime by 15-30% and boost asset availability by more than 20%.

Manufacturers need a practical playbook

Historically, an ERP modernization project meant a multi-year effort defined by large costs and significant operational effort. AI-enabled ERP overcomes this barrier by reducing the need for complex customization, shortening implementation cycles and providing built-in intelligence that rapidly adapts to shifting business conditions.

However, even with these advantages, mid-sized manufacturers still require a clear, practical roadmap. Without one, the gap between strategic vision and successful execution remains vast.

Many of the most successful customers I’ve worked with follow this kind of focused framework:

- Baseline current operations and pinpoint the challenges. Begin by rigorously examining chronic downtime, persistent maintenance backlogs, planning delays, operator workarounds and data inconsistencies. This establishes a fact-based starting point and prevents technology decisions driven by assumption.

- Identify high-value use cases across the value chain. Evaluate potential AI-powered use cases across every relevant area, such as procurement, supply chain, production, asset management and finance. Prioritize the cases with the clearest business ROI and the potential to demonstrate tangible results within a focused 60-90 day timeframe.

- Evaluate technology providers using clearly defined criteria. Manufacturers must compare vendors based on embedded AI capabilities, ease of integration with existing execution systems, overall scalability, total cost of ownership and the level and type of organizational change required. The objective here is to select technology that aligns with the organization's current and future operating reality.

- Prepare for implementation with aligned success metrics. Stakeholders must agree on concrete success metrics, whether it's improving OEE (overall equipment effectiveness), boosting productivity or reducing TCO (total cost of ownership). Early engagement with plant teams, meticulous data preparation and a commitment to short, iterative implementation cycles are critical for building momentum and confidence.

More AI and ERP insights from Automation World:

About the Author

Chao Yi

Chao Yi is a technology executive with deep expertise in cloud ERP and manufacturing strategy. He currently serves as a vice president of product marketing at SAP. Prior to SAP, he was a project leader at Boston Consulting Group (BCG), advising U.S. manufacturers on digital transformation. The views expressed in this article are those of the author and do not necessarily reflect the position of his employer.