Why the U.S. Risks Falling Behind China in Humanoid Robots

- Humanoids are demonstrating unmatched versatility in warehouse operations, performing multiple tasks across shifts with minimal IT integration or infrastructure changes.

- China is accelerating humanoid adoption, creating a feedback loop of innovation, while U.S. progress lags due to cultural skepticism and economic hesitation.

- ROI and labor efficiency calculations could drive greater humanoid adoption with their long-term savings and operational flexibility, especially in multi-shift environments.

In the warehouses that power global commerce with goods connected to every manufacturing vertical industry, a change is beginning to take shape. This change isn't about faster conveyor belts or smarter sorting systems; it's about humanoid robots.

Adrian Stoch, CEO Americas at Hai Robotics and former chief automation officer at GXO Logistics, can almost hear your laughter and see your eyerolls at this statement. But he believes humanoid robots represent the most transformative technology to hit manufacturing and warehouse operations in decades — and he’s in a position to separate the hype from reality.

"I can't stress enough how this is going to change warehouse logistics," Stoch said during his keynote presentation at the RoboGeorgia 2025 Summit, held at the Georgia Tech Research Institute. "Humanoids are going to change warehouse logistics."

You look at the ROI, comparing what it costs compared to the cost of labor. If it's a positive number within five years, you can move forward. This is even more dramatically different with humanoids, because of their flexibility, pace of work and the hours that they can work. These are opportunities that exist in this category that don't exist elsewhere.

The game changer: Humanoids’ flexibility factor

Stoch stressed that what makes humanoids so revolutionary isn't their human-like appearance, it's their versatility. Unlike traditional automation that excels at single, repetitive tasks, humanoids represent what Stoch called "the only category of technology that can have the same units performing different tasks throughout the day."

Picture this: the same robot that unloads a trailer at dawn can pick products from shelves in the afternoon and prepare shipments for departure by evening. Stoch said this flexibility addresses one of automation's biggest limitations — the need for specialized equipment for each function, often requiring complex IT integration and extensive facility modifications.

Humanoids’ ability to perform very different tasks, requiring very low IT integration and coupled with their high levels of interaction with other material handling equipment mean that manufacturers and warehouses can deploy humanoids without the massive infrastructure overhauls typically associated with automation projects.

The base technology (for developing capable humanoids) is all there. I've seen it working, and the recent rate of progress [in China] has been way faster than what I'm seeing in the U.S.

Why China is leading the way with humanoids

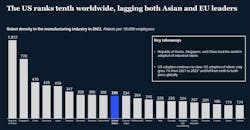

But Stoch's optimism turns to concern when he considers how humanoids are viewed globally. From Stoch’s point of view, the United States risks falling behind in its development and deployment of humanoids — not for technological reasons, but cultural and economic reasons.

"We're years away from seeing humanoids in wide deployment in the U.S., but not in China,” he said, “because there is big demand side push in China for humanoids, which will help the tech mature faster there.”

According to Stoch, this demand-side difference creates a feedback loop where Chinese companies will gain more experience, iterate faster and ultimately develop more capable humanoids.

A key driver of this difference in opinion about humanoids can be seen in a cultural divide that runs deeper than market demands. Stoch pointed out that Western media have long portrayed humanoid robots as sinister threats, like those seen in the Terminator or Ex Machina. In contrast, Asian cultures often depict these robots as friendly helpers, working alongside children to solve problems.

"This is not a trivial point," Stoch warned. "It's going to be a barrier that we're going to have to overcome in the U.S."

Make no mistake, Stoch did not come across as a starry-eyed technophile enamored with the possibility of humanoids in industrial applications. He recognizes the hurdles that humanoid robot tech still has to overcome. For example, he referenced work by Agility Robotics, where teaching a humanoid robot its first warehouse task — simply picking up totes and moving them to a conveyor — took two months of training. When the process changed slightly, requiring the robot to learn a variation that would take a human worker an hour to master, it took the robot weeks.

We're years away from seeing humanoids in wide deployment in the U.S., but not in China, because there is big demand side push in China for humanoids which will help the tech mature faster there.

Despite these challenges, Stoch stressed that "the base technology (for developing capable humanoids) is all there. I've seen it working, and the recent rate of progress [in China] has been way faster than what I'm seeing in the U.S.," noting what he called the "staggering" advances he’s been seeing coming out of China in just the last six months.

The stakes extend beyond individual companies to national competitiveness. As Chinese organizations demonstrate greater willingness to adopt humanoid technology quickly, they're creating a virtuous cycle of innovation and improvement. "Chinese organizations are going to be more prepared, more motivated, more incentivized to adopt quicker and that's going to even further push the innovation," Stoch predicted.

Safety and economic considerations

For humanoid research to accelerate here in the U.S., leading to greater adoption of the technology, Stoch said several obstacles must be faced. Foremost among these are safety and regulatory compliance. Stoch noted that industry groups are currently working to establish standards for this unique category of flexible automation. One of these is the ISO 25875 standard which, according to Agility Robotics, has recently been accepted for review by ISO.

Unit economics are perhaps the most compelling case for humanoids, said Stoch. “It's a very simple calculation we would do at GXO with any customer. You look at the ROI, comparing what it costs for individual purchases, and you compare it to the cost of labor. If it's a positive number within five years, you can move forward with the transactions. This is even more dramatically different with humanoids, because of their flexibility, pace of work and the hours that they can work — you can have the humanoid work on a second shift or even a third shift when there aren't humans in the building. These are opportunities that exist in this category that don't exist elsewhere.”