Dual Collision Detection Technology Extends Cobot Reach and Safety

Key Highlights

- A single cobot mounted on the Movotrak can cover up to 10 meters of stroke with ±25 microns accuracy, potentially replacing four to five stationary cobots in applications ranging from palletizing to welding inspections and automotive assembly.

- Collision detection sensitivity can be adjusted during setup, with safeguard logic running in the Thomson drive rather than the robot controller to minimize bandwidth competition and maintain responsive safety monitoring throughout operation.

- Freedrive functionality enables operators to manually position and program waypoints by sliding the cobot along the axis.

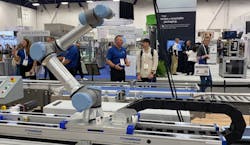

As collaborative robots (cobots) are increasingly adopted across the manufacturing industries, workspace limitations have emerged as a constraint on the deployment of cobots in applications requiring extended reach. Regal Rexnord's Thomson looks to address this issue with its Movotrak CTU (cobot transfer unit) 7th axis. The company calls Movotrak "the first ever true collaborative extension for cobots."

A key feature of the Movotrak is its dual collision detection system to maintain the safety of workers working near the 7th axis system across the range of the system’s extended linear motion.

To learn more about Movotrak, we met with Pablo Olachea with Regal Rexnord at Pack Expo 2025.

Establishing a new level of safety for 7th axis tech

Movotrak’s two-tiered approach to collision detection employs both hardware and software-based safety mechanisms, explained Olachea. "You have two collision detection modes basically, and that's what makes it different," Olachea explained. "The first collision detection is basically a load cell within the carriages, and this one engages with 13 Newtons of force."

The second collision detection feature is a patent-pending approach which puts current and the servo drive data into an algorithm. This enables the system to continuously monitor current in the Kollmorgen servo motor, detecting position to provide anti-collision capabilities along the entire 7th axis. Following a collision detection event, the system includes a small reverse-move feature that eliminates pinch points after a stop — a critical safety enhancement for collaborative environments.

These factors are “what gives us the edge on the collision detection," said Olachea. The collision detection system's sensitivity settings can be adjusted on a control tablet during setup, with the Movotrak CTU motor drive and digital I/O managing collision monitoring and shutdown functions.

Expanding cobot reach for improved ROI

The Movotrak system’s linear-unit-driven guide rails transport cobot assemblies from one task location to another. These rails are available in horizontal, inverted or wall-mounted configurations. With accuracy of ±25 microns over the entire stroke, Thomspon Industries says the system can maintain precision across its extended distances.

Without a 7th axis system, you may need several cobots aligned together to work on an application, noted Olachea. “But with the seventh axis system, you can remove some of those cobots to have just one with 10 meters (30+ feet) of stroke doing all the work that four or five robots would be needed to do without the seventh axis," Olachea explained. "That will give you a better ROI from your cobot investment."

Applications for Movotrak span multiple industries. Olachea cited palletizing operations, welding inspections, and automotive assembly as examples where the extended reach delivers measurable productivity gains by consolidating multiple stationary cobot installations into a single mobile unit.

Movotrak integration and programming aspects

Thomson notes that Movotrak integrates with many cobot sizes and brands, with all collision monitoring and safeguard logic running in the Movotrak drive to minimize bandwidth competition with robot controls. "The URCap (Universal Robot’s partner program) provides all the necessary plug-in I/O components to work with UR cobots," said Olachea. "We also have an add-in for ABB and, by the end of the year, we'll have something for Fanuc. But we can work with the customer to build what they need for any kind of robot they want to use."

For Universal Robot users, all programming can be done directly through a URCap interface on the UR Teach Pendant, streamlining the deployment process.

Freedrive simplifies waypoint programming The Movotrak includes freedrive functionality similar to cobot joints, enabling hand-driven setting of linear waypoints during programming. Users manually slide the cobot to desired positions along the 7th axis and register locations with a push button.

This feature proves particularly valuable for applications requiring repeated positioning. An aircraft quality inspector, for example, could set up inspection sequences for repeated imaging of the same areas over time. Similarly, a welder could efficiently program welding sequences at multiple locations without complex teach pendant procedures.

In the video interview below with Regal Rexnord’s Pablo Ochea, he explains Movotrak’s safety features, cobot integration, applications and programming.