The concept of test-centric assembly is very straightforward. It essentially means designing and engineering assembly systems with a priority placed on failsafe/foolproof testing. The results commonly attributed to the test-centric assembly process include improved throughput, yield, system uptime and time-to-market.

Taking the concept a step further, InterTech Development Company (a supplier of automated leak and functional testing products) says that test-centric assembly is not just a process, but a strategy. As a production strategy, test-centric assembly requires that test engineers “be granted equal place on the teams that design/engineer production and assembly systems,” according to Jacques Hoffmann, president of InterTech Development Company.

The reason Hoffman says this step is necessary is due to the costs associated with poor implementations of quality control in assembly, such as leak testing. Those costs are directly related to:

• The direct costs of rework, re-inspection, and re-testing of rejected shipments (if the shipment was not scrapped);

• Erosion of profits due to recalls; and

• Negative consequences of a systemic quality failure, including permanent damage to corporate and personal reputations.

With test-centric assembly, specific attention is paid to processes that go into production such as how a product is sealed, filled and stabilized. “Everything for the test process is optimized, including considerations for thermal effects such as ambient or part temperature,” says Hoffman.

A major benefit of test-centric assembly, according to Hoffman, is how easily its return on investment can be accounted for. “Test-centric assembly pays for itself in many ways,” he says. For example:

• Rework is cut by 20 percent or more, because only good parts are shipped to customers and because problems are identified early and fixed earlier in the process;

• Process improvements include the advantage of fewer test stations (often by half), which leads to CAPEX savings of 50 percent or more;

• Gage repeatability and reproducibility creates reliable, useful feedback for more efficiency; and

• Less maintenance and, in some cases, a reduction in consumables such as helium.

“Test-centric assembly is much more than out-of-the-box thinking,” says Hoffman. “It is the lean manufacturing equivalent of testing. Test-centric assembly has a ripple effect in that it becomes the central focus of production and radiates to faithful performance of a product throughout its life.”

To explain the test-centric assembly process, InterTech has created a white paper (available at www.intertechdevelopment.com) that details leak testing and examines how to achieve a failsafe process for such testing. The paper explains test-centric assembly for mechanical engineers, test engineers and management by illustrating how collaboration of testing expertise and production planning creates faster, more flexible and cost effective assembly.

Some of the topics addressed in the white paper include:

• Why dry air is the testing medium of choice in everything from catheters and assisted breathing devices to heat transfer units, solenoid valves and hydraulic systems;

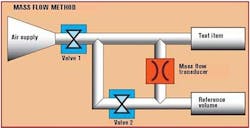

• Comparisons of mass flow and pressure decay testing processes;

• Why commercially available mass flow sensors are not designed for leak testing;

• How advanced manufacturing processes involving robots, mechatronics and real-time data for statistical process control can place contradictory demands on test intensive production;

• Leak testing circuits;

• Ethernet and I/O connections;

• Traceability; and

• Calibration and validation.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: