How Semantic Intelligence Helps Manufacturers Cut Crisis Response Time from Weeks to Days

Key Highlights

- Supply chain disruptions surged 38% in 2024, yet most manufacturers take two weeks to respond when they have just 72 hours to avoid major impact. Semantic intelligence can compress this reaction time to two days.

- Traditional systems failed during the chip shortage because they couldn't see beyond tier-one suppliers or understand that one component change would cascade through dozens of dependencies across the production network.

- Organizations implementing semantic intelligence report 85% faster crisis assessment, 40% better production resilience and 15-20% lower disruption costs by transforming static data into dynamic, contextual knowledge graphs.

In 2021-2022, Ford had thousands of F-150 trucks sitting at Kentucky Speedway, an inactive speedway in Sparta, Kentucky. These were $50,000 vehicles waiting for chips worth less than $50.

Meanwhile, General Motors and Stellantis faced similar paralysis as semiconductor shortages collided with COVID lockdowns, a major Texas winter storm and the Suez Canal blockage. Collectively, they lost more than $110 billion in production. Meanwhile, The New York Times reported that Tesla grew production 87% during the same period. The reason: Their engineers could rapidly identify alternative chips, rewrite firmware and adapt production to make decisions in days rather than months.

The difference was not better planning. It was about understanding context and relationships through semantic intelligence, the capability to understand the meaning and context of data across systems, not just process it.

The new manufacturing reality

According to Resilinc, a supplier of agentic AI supply chain risk management technology, supply chain disruptions increased 38% in 2024. McKinsey reports that disruptions lasting more than a month occur every 3.7 years on average, costing businesses up to 45% of annual profit over a decade. The response time available to correct these issues without significant impact is 72 hours. The actual response time for most companies, however, is two weeks.

These numbers reveal a real problem — disruption is outpacing the industry’s ability to understand its own data. Without shared context, manufacturers lose precious days just trying to piece together impact before they can act.

Three failure modes of traditional systems

Opacity: The visibility crisis. During the semiconductor crisis mentioned earlier, manufacturers discovered they couldn't see beyond tier-one suppliers. A modern vehicle contains 1,000+ semiconductors, but traditional systems showed only direct relationships. They couldn't reveal that a module contained 30 chips from 12 different foundries, or that a Malaysian supplier shutdown would halt Michigan production six weeks later.

Brittleness: The cascade effect. When Boeing developed the 787 Dreamliner, carbon fiber specifications required unanticipated manufacturing process changes. The cascading impacts through engineering, suppliers and regulations delayed first flight from 2007 to 2009. One change triggered dozens of system updates — a brittleness that persists across industries.

Fragility: The integration breakdown. Traditional systems record transactions but don't capture context. They show information such as "component received from supplier" but miss "this component depends on rare earth materials from three countries and affects seven product lines worth $30 million in monthly revenue."

Semantic intelligence: Context as infrastructure

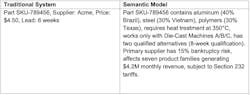

Semantic models create knowledge graphs on top of transactional systems. They detail the networks of entities, relationships and rules that mirror business reality to transform static records into dynamic context. Here’s an example:

In this example you can see how the richness of the semantic model powers automated reasoning. When tariffs change, the system immediately identifies affected products, calculates margin impacts, suggests alternatives and models changeover costs without manual analysis.

Use case example

During the chip shortage in 2021-2022, a major automotive manufacturer implemented semantic modeling to map semiconductor dependencies. The system revealed:

- 1,200+ unique semiconductor parts.

- 60% of supposedly “diversified" suppliers depended on three foundries.

- 400+ potential substitutes requiring firmware modifications.

When chip availability shifted weekly, this semantic system could identify which production lines to prioritize, calculate revenue impacts, propose substitutions and optimize allocation across facilities. As a result, decision cycles compressed from two weeks to two days.

The February 2021 storm in Texas highlighted the difference. Companies with semantic models could immediately trace dependencies and identify alternatives. Those without spent weeks in Excel trying to understand their exposure.

Building agile operations

These three principles guide semantic transformation:

- Make the semantic layer primary architecture. Don’t treat semantic models as analytics add-ons. Make them the primary abstraction where business logic lives. Manufacturers restructuring with semantic cores report 70% reduction in integration complexity.

- Become resilient to incomplete information. Semantic models support probabilistic reasoning when information is incomplete. For example, during the Suez Canal blockage, semantic systems provided 80% confidence estimates enabling decisions in hours, not weeks.

- Evolve locally, while staying globally aligned. Different facilities extend models locally while maintaining global coherence. When FDA authorizations changed weekly during COVID, semantic models updated immediately with impacts propagating automatically.

All three of these principles are needed to scale. Relying on one method only can cause distortion or misrepresent reality.

Latest-generation systems, such as The Modern Data Company’s DataOS capture context by ingesting day-to-day management and business operations knowledge in the form of plain language documentation to discover pre-existing relationships in data systems and train data systems via AI.

But even with these capabilities, humans must remain in the loop to build effective intelligence.

To build a solid foundation for a semantic layer, four human skills are needed:

- Subject matter expertise at the business level. Manufacturing excellence staff know their data. They can distinguish between “input temperature” and “output temperature” by just looking at the data. They can tell what data point may be an outlier.

- Process knowledge via systems. Business analysts who designed the systems or are maintaining the systems that produce the data and know what internal transformations the data is going through.

- Data modelers. This is becoming an increasingly rare skill, as these are technologists and architects of data ecosystems. If they come with too much experience from the past, it may be hard for them to envision the future and bring in agility. And if they were born in the modern data stack era, they may not envision the challenges of legacy systems.

- Data analytics professionals. These experts can apply simple to complex statistical techniques to create metrics, define algorithms to optimize, discover patterns across data ecosystems, use AI and more.

It can be a challenge to find more than two skillsets in a single person. But it is good to keep this framework in mind to create a team topology that drives scale. And it’s worth the effort to do so. Organizations implementing semantic intelligence report an 85% reduction in assessment time, 40% improvement in production resilience and 15-20% reduction in disruption costs.

More data intelligence insights from Automation World:

About the Author

Sagar Paul

Sagar Paul is senior vice president of global growth and solutions at The Modern Data Company.