Siemens and Snowflake Enable IT/OT Convergence

Siemens is collaborating with Snowflake, the AI data cloud company, to help manufacturers connect their operational technology (OT) data from the shop floor with information technology (IT) data, such as supply chain management and financial data.

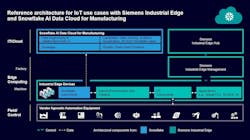

According to the two companies, by connecting Siemens Industrial Edge and Snowflake’s AI Data Cloud, manufacturers can access plug-and-play Industrial Edge applications to contextualize and transfer OT data into IT systems. This integration enables manufacturers to build the data foundation required for gaining deeper insights, improving machine performance, increasing machine availability and optimizing production processes across their facilities.

Here’s how the two systems work together. Siemens Industrial Edge is designed for production managers, data engineers and IT leaders to address common challenges such as data silos, limited transparency and inefficient analytics. It does this by connecting to a wide range of sources, including PLCs, sensors and other manufacturing systems to pre-process data at the edge before using it in OT data models for closed-loop production automation applications. With the data properly processed, Snowflake’s platform delivers operations insights through AI-powered analytics and agentic AI capabilities. The result is a measurable boost in operational efficiency, with higher machine performance, enhanced product quality and reduced maintenance needs.

FFT, a provider of automation components, systems and integration services, uses the Siemens Industrial Edge ecosystem to help manufacturers securely transfer production data into the Snowflake AI Data Cloud through its DataBridge app. FFT is already using this on its own production lines and facilities, demonstrating its capability to meet the company’s highest standards of efficiency and data-driven optimization.