Electric Actuators for High-Mix Production: How Smart Design Reduces Changeover Time and TCO

Key Highlights

- Actuators with built-in encoders and precision guidance enable position, speed and force adjustments on-the-fly without mechanical reconfiguration or production delays.

- Integrated diagnostics monitor temperature, cycle counts and load variations to anticipate maintenance needs and prevent costly downtime before failures occur.

- Electric actuators eliminate hydraulic expenses like pumps, fluid changes and leak risks while operating at 95%+ efficiency for faster ROI in high-duty applications.

Product changeovers are a common manufacturing procedure that have traditionally required time-consuming mechanical adjustments of actuators. Automation technology suppliers have been responding to this with designs for electric actuators that are tailored to high-mix production.

Core engineering advancements make these new actuators more adaptable, precise and easy to install than their predecessors, minimizing the mechanical work required during changeovers.

Matt Prellwitz, drive technology product manager at Beckhoff, described how an electric actuator’s basic design ensures precise, high-performance operation, referencing Beckhoff’s AA3000 and AA3100 series actuators as examples. “For a number of years, we worked with third-party electric actuators. And whenever we did that, we had to add limit switches [and other components to get them to home properly]. And that was really a combination for misuse. So we made an electric cylinder with an internal anti-twist assembly [for highly repeatable operation in a compact package], and we based it on the mechanical standard for the ISO 15552 pneumatic cylinder.”

The core trade-off in high-mix production is not between cost and performance, but between short-term component pricing and long-term TCO.

These actuators support force up to 25 kN (A3000) and 12kN (AA3100). Prellwitz added that “these actuators are very, very quick. It's only 150 to 250 millimeters of stroke length, but they can travel at speeds of one meter per second.”

Manufacturers should be on the lookout for features such as high-efficiency ball screws and precision guidance systems to ensure accuracy at high speeds. Also, watch for the availability of reconfigurable mounts and tool-less changeover to help simplify installation and repositioning without requiring total disassembly.

Florent Orget, Emerson’s product marketing manager for actuators, noted that “in high-mix environments, balancing flexibility and throughput often comes down to intelligent actuator design and integrated motion control.”

In high-mix environments, engineers should isolate the true bottlenecks — those parts subject to tight tolerances or residing on a critical path — and mark these as candidates for premium actuators.

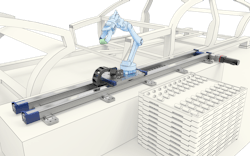

According to Emerson, its Aventics electric actuators, when paired with compatible servo drives and controllers, allow for rapid changeover without mechanical adjustments. “By standardizing on modular actuator platforms and using pre-programmed motion profiles, manufacturers can switch between product variants quickly while maintaining consistent cycle times,” said Orget.

A recurring theme from electric actuator suppliers is that mechanical innovation combined with digital control and configuration of core functions reduces the need for reconfiguration.

Tom Worsnopp, product marketing manager for electric automation at Festo, contends that “when we talk about balancing high mix versus cycle times, it's almost not a trade-off because an electric actuator provides flexibility almost for free. You can move to any position you want. You can change your speeds, your forces, all on the fly. So, you don't really have to take a bump at all on cycle times. The actuator can move to any position you want because there's encoder feedback on the motor that tells the user where it’s at. This means you can change the speed to anything you want, between movements even or in the middle of a movement.”

Electric actuators’ supporting technologies

Electric actuators are really a combination of multiple, highly engineered technologies, as end user requirements for speed, torque and position might change with every product.

Rene Ymzon, marketing manager at Advanced Motion Controls (AMC), explained that the servo drive is what "fills the gap" between an actuator’s mechanical envelope and the performance required, running the actuator through the whole spectrum of torques and speeds it is capable of. “The key differentiator,” he said, “is the robustness of the control algorithms.”

For example, AMC’s gain scheduling feature allows drives to be pre-tuned for multiple operating parameters. Instead of detuning the system to handle a wider range of products, users can switch between these tuning profiles with a single command, ensuring that they get “peak performance regardless of which scenario they're running,” said Ymzon.

Another drive feature, called notch filters, removes problematic resonant frequencies inherent in a machine's structure, allowing the user to maintain high tuning values without causing instability, noted Ymzon.

If it is a high duty cycle application, the electric actuator will always give you a return on investment very quickly, running at 95% or more power efficiency.

High-speed communication is also fundamental to precise, optimized servo drive control and electric actuation. Ethernet-based protocols like EtherCAT, Profinet and EtherNet/IP facilitate the rapid, tight control and high-speed data exchange necessary for adaptive performance.

Chuck Lewin, CEO of Performance Motion Devices (PMD), pointed out that miniaturization of control components has advanced so far that they can now fit inside the actuator itself. This allows for greater localization of a servo drive, which adds to performance because motion accuracy improves when signals have less distance to travel, thereby reducing noise and delay.

In applications where manufacturers need to reconfigure quickly without losing speed or accuracy, the real difference-maker can be how smart the drive is and how quickly it can communicate with the rest of your motion control system.

That’s why many modern motion control systems are replete with features that help maximize the lifespan of actuators. These features also give integrators and end users several inroads for data collection.

Emerson Aventics actuators, for example, include built-in condition monitoring to track metrics such as temperature, cycle counts and load variations, to anticipate service needs. And Beckhoff's integrated diagnostics can read the shock forces in X and Y axes, providing a warning against side loading (radial loads), a known failure point for linear electric actuators.

The higher price of electric actuators often reflects an ability to absorb the costs and problems of other parts of the system.

Connected to the motor, feedback and power supply, servo drives can also supply a host of valuable data for predictive maintenance. If a machine takes 3.2 amps for a move in January but 4.1 amps to do the exact same move six months later, it may signal that something needs to be lubricated or a bearing is going out.

Integrated vs. best of breed

One of the biggest decisions facing manufacturers when it comes to flexibility, is whether to purchase a fully integrated system from a single supplier or build a custom system by mixing and matching components from different vendors.

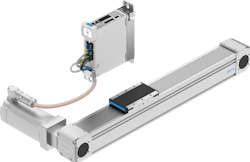

Worsnopp argued for the integrated approach, noting that if a customer receives the actuator, motor and drive from a single manufacturer, they have a "sense of security" knowing the system was "designed to work together." This guarantees component compatibility and minimizes the customer’s integration and testing burden.

Manufacturers should be on the lookout for features such as high-efficiency ball screws and precision guidance systems to ensure accuracy at high speeds.

However, he also acknowledged the counter argument, noting the risk of putting "all your eggs in one basket" if a single supplier fails to deliver. Still, he stressed that the simplicity of a single parts list and verified components appeals to more customers.

Ymzon acknowledged that packaged systems may be a better fit for most installations, but there are many cases where a best-of-breed approach is necessary. He said this often occurs when packaged systems can’t meet performance criteria, require atypical voltage ranges or have space constraints that impose non-standard components. AMC addresses this by providing servo drives with the flexibility to work with "any motor, any controller, any feedback," said Ymzon.

Justifying cost through efficiency

So, are all these bells and whistles that come with modern electric actuators and related drive systems worth it?

The suppliers we spoke to point out that the higher price of electric actuators often reflects an ability to absorb the costs and problems of other parts of the system. They caution that focusing on the initial bill of materials (BOM) cost is “a common mistake” and urge designers to prioritize long-term total cost of ownership (TCO).

For example, compared to traditional hydraulic actuation, electric actuation can remove substantial hidden operational costs associated with fluid power. Travis Gilmer, global product manager for linear actuators at Thomson/Regal Rexnord, said that an $80 hydraulic cylinder might be attached to a $150 pump with $50 of tubing and $30 of fluid that you have to change every three months. These costs, alongside the risk of leaks and environmental safety concerns, disappear with electric systems.

Beckhoff’s Prellwitz also noted that electric systems can offer significant energy savings. “If it is a high duty cycle [application],” he said, “the electric actuator will always give you a return on investment very quickly, running at 95% or more power efficiency.”

Ymzon added that integrated safety features like a built-in safe torque off (STO) feature on a servo drive can reduce TCO by removing the need for expensive external safety components.

When balancing high mix versus cycle times, it's almost not a trade-off because an electric actuator provides flexibility almost for free.

When comparing one electric actuator to another, Matt Moseman, CEO and founder of system integrator Develop cautioned that any investment should be proportional to risk. He pointed out that a "$600 actuator that lasts six months and requires two hours of downtime to replace is way more expensive than a $1,500 one that runs cleanly for five years." This is how the increased reliability of an electric system directly minimizes this cost of downtime.

However, higher component cost doesn’t always indicate better TCO.

Moseman noted that, in high-mix environments, engineers should isolate the true bottlenecks — those parts subject to tight tolerances or residing on a critical path — and mark these as candidates for premium actuators. The remaining axes can be designed for easy, tool-less changeover, accepting a slightly slower movement if it saves minutes in retooling.

Gilmer said that by prioritizing critical features, such as high load handling and speed over aesthetics or sound, manufacturers can be better positioned to source an actuator that perfectly fits the application while avoiding the cost of an over-specified solution.

Another factor to hitting the cost-performance sweet spot requires ensuring fitness for purpose. Orget stressed the need to define the motion profile first and then select the actuator that meets those parameters with the lowest TCO.

Festo approaches this through its product selection tool, which it claimed is designed specifically for this kind of up-front engineering, allowing users to input critical motion parameters and identify the lowest cost viable solution.

Trade-off considerations

The core trade-off in high-mix production is not between cost and performance, but between short-term component pricing and long-term TCO. That’s why manufacturers should shift their perspective to view the actuator as a digitally enabled, integrated component that drives efficiency across the entire system.

With this in mind, look for mechanical design features that allow an actuator to perform optimally across key process segments while providing comprehensive data services to enable predictive maintenance for long-term operation. This strategic approach transforms the electric actuator from a simple mechanical component into an intelligent, cost-saving asset.

About the Author

Josh Eastburn

Josh Eastburn earned his degree in computer science from California Polytechnic University and spent over a decade as a control systems integrator, automation engineer and project manager. His engineering work has included a wide range of DCS, SCADA, PLC and HMI projects across multiple sectors, including semiconductor, petrochemical, food and beverage, and life sciences.