Dorner

Hartland, WI 53029-0020

United States

Product Summary

More Info on Dorner

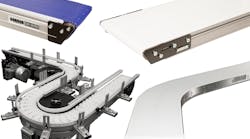

At Dorner, our mission is to Transform Conveyor Automation by providing cutting edge solutions with best-in-class support. It’s that commitment and history of proven excellence that has made the Dorner Brand a recognized leader in product handling for over 55 years. With our complete line of customizable stainless steel and aluminum conveyor automation systems, Dorner can provide solutions for almost any conveyor need.

Dorner’s conveyors are designed to move product to the exact location, at the exact time and in the exact position it needs to be for the next phase of the production line. With benefits such as industry best product transfers and in-house belting capabilities, Dorner is leading the market in precision conveyance. This extremely accurate product control allows Dorner conveyors to easily integrate with robots, workers and equipment.

Dorner’s Engineered Solutions Group (ESG) is transforming product handling with innovative solutions that are custom designed to solve customers’ unique needs. This full service team can provide systems for applications such as accumulation, indexing, positioning, product flow and much more.

Additional Dorner benefits:

- After sales support through services such as installation, maintenance, replacement part audits, and preventative maintenance programs

- Industry best lead times with conveyors shipping in as few as three business days

- Online Configurator (D-Tools) allows users to design conveyors and download 3D CAD Assemblies for instant validation of fit

Visit our website to learn more: www.dornerconveyors.com