igus, Inc.

Rumford, RI 02916

United States

Product Summary

More Info on igus, Inc.

The family-owned company is committed to using its innovative materials to develop creative solutions and exceed customer expectations while delivering fast, accurate service. igus’ polymer blends are used throughout its range of product lines of cable carriers, continuous-flex cables, plastic bushings, linear bearings and guides, automation solutions, and more.

igus engineers develop over 100 new polymer compounds each year for use across every product line. Each material is tested extensively in the igus test lab in Cologne, Germany. More than 10,000 tests are conducted on each material to analyze tribological properties, wear resistance and more, and all results power various online tools and an extensive material database. With this data, igus engineers can offer a precise lifetime prediction for bearings and linear systems in nearly any application.

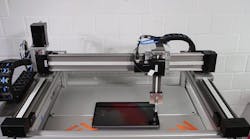

igus for automation & robotics manufacturers

Products from each of igus’ major product lines can be used effectively within automation applications. drylin® linear, gantry and delta solutions as well as iglide® plastic bearings offer 100% dry-running, maintenance-free, and oil and grease-free operation at an overall cost savings when compared to metal linear and plain bearing systems, and e-chain® cable carriers and chainflex® cables work in tandem to create a reliable energy supply for nearly any robotic solution.Contact our team of product experts for help with your application or choose from a range of online tools to select your ideal system, calculate lifetime, download CAD files, and more. White papers, application examples, videos & more available at https://toolbox.igus.com/low-cost-automation

Learn more about igus® at https://www.igus.com/